It’s easy to take the smart controls in our factories for granted today. Flick a switch, and a complex assembly line hums to life, orchestrated by unseen digital brains. But these systems, the Programmable Logic Controllers (PLCs) we rely on, have a fascinating history. My years spent sifting through dusty archives revealed the ingenious steps that led us here.

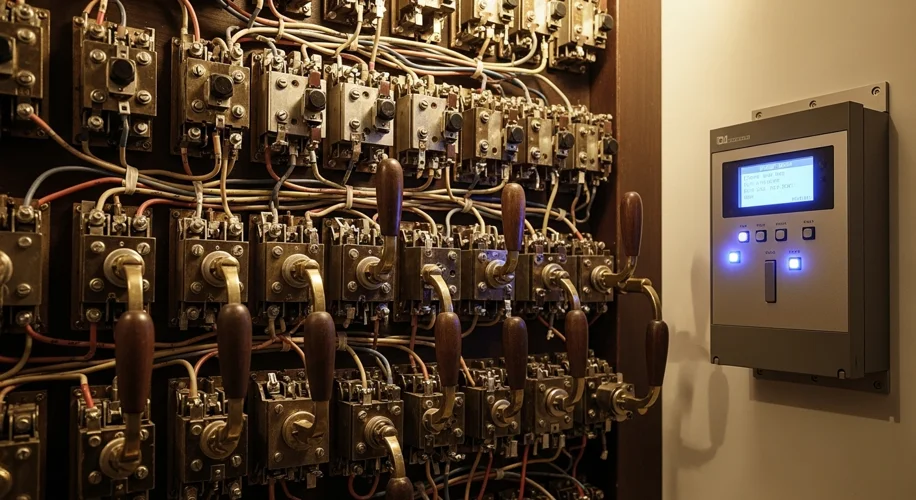

Before PLCs, automation in factories relied heavily on electromechanical relays. Think of a vast, intricate switchboard, a physical manifestation of logic. If you wanted to control a machine, you’d wire together hundreds, sometimes thousands, of these relays. Each relay acted like a simple switch, opening or closing a circuit based on an input. Complex sequences were built by linking these relays in specific ways. It was clever, but incredibly cumbersome.

Imagine trying to change a production process. You wouldn’t just type in a new program. No, you’d have to physically rewire the entire system. This was time-consuming, prone to errors, and made flexibility a distant dream. These early systems were the workhorses of manufacturing, but they were also rigid and incredibly complex to maintain. The sheer physical space and the constant need for adjustments were major limitations.

Then came the technological leap: the transistor and, subsequently, integrated circuits. This paved the way for digital control. Instead of bulky relays, engineers could use solid-state electronics. The real breakthrough, however, was the advent of the microprocessor in the early 1970s. This tiny chip could store and execute instructions, allowing for a much more flexible and compact control system.

This is where the Programmable Logic Controller, or PLC, truly began to take shape. Companies like General Motors, seeking a more efficient way to manage their automotive production lines, were instrumental in pushing for these new systems. They needed something that could be reprogrammed without extensive rewiring, something that was more reliable, and something that could handle the demands of mass production.

The first PLCs, emerging in the late 1960s and early 1970s, were essentially ruggedized computers designed for industrial environments. They replaced the entire relay panel with a single, programmable unit. This was a monumental shift. Suddenly, changing a machine’s sequence or adding a new feature meant updating software, not climbing into a tangle of wires.

The impact on manufacturing was profound. Processes became more consistent, maintenance was simplified, and factories gained a level of agility they’d never known. This evolution wasn’t just about replacing one piece of hardware with another; it was about fundamentally changing how we could design, build, and adapt automated systems. It’s a testament to the ingenuity of those early engineers who saw beyond the limitations of relays and embraced the dawn of digital control.